Turned parts

The task.

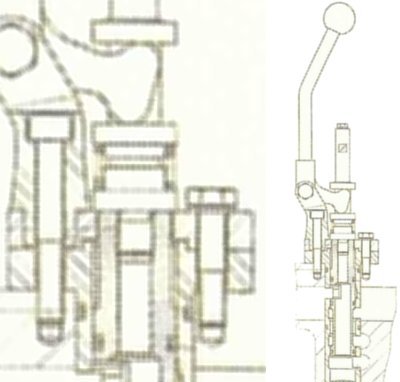

Production of a stainless steel sleeve with a different inner profile, which serves both as a guide and protection bush for the injection nozzle in industrial and marine engines.

The special features.

The sleeve must be made from solid material, as the inner profile does not allow the use of tube. Furthermore the inner sealing surface of the sleeve must run exactly parallel to the exterior thread; the tolerance limit is below 0.04 mm in this case (The combustion engine can only develop the full power, if the injection nozzles are in their absolutley correct position).

Compared to standard chrome-nickel alloy steels, the stainless steel A 4 used has excellent anti-corrosion protection qualities, but is extremely resistant to being machined. Traditional turning is therefore impossible, as it woul generate very high processing temperatures, leading to extreme wear of the cutting tools and the consequent deterioration of surface quality.

The solution.

How we solved this task can be read in our information brochure which can be obtained for free. Just send an email request to info@feldmann-mab.de.